Team:Washington-Software

From 2009.igem.org

(Prototype team page) |

|||

| (118 intermediate revisions not shown) | |||

| Line 1: | Line 1: | ||

| - | + | {{:Team:Washington-Software/Header|in}} | |

| - | < | + | <h2> Abstract </h2> |

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | </ | + | |

| - | < | + | <h4>'''BioBrick-A-Bot: Lego Robot for Automated BioBrick DNA Assembly'''</h4> |

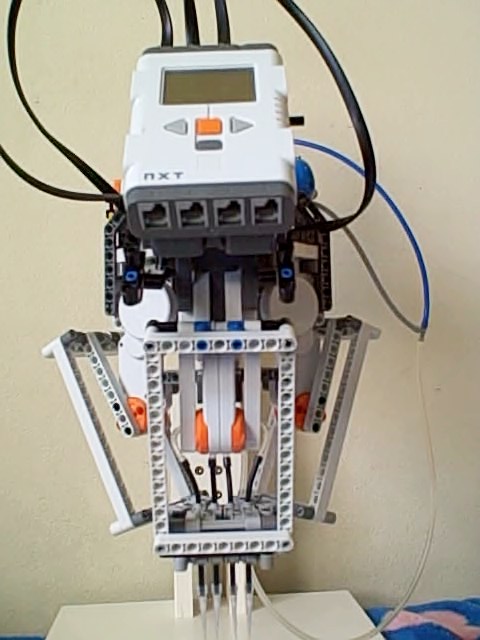

| + | [[Image:Robot Close Up.jpg|thumb|right|'''BioBrick-A-Bot''']] | ||

| + | Commercial Liquid Handling Systems are extremely expensive, and are typically beyond the reach of the average molecular biologist interested in performing high throughput methods. To address this problem, we design and implement a liquid handling system built from commonly accessible Legos. Our goal is the automation of BioBrick assembly on a platform that can itself be easily replicated and we demonstrate a proof-of-principle for this system by transferring colored dye solutions on a 96-well plate. We introduce a new concept called LegoRoboBrick. The liquid handling system is build from 3 new LegoRoboBrick modular components: ALPHA (Automated Lego Pipette Head Assembly), BETA (BioBrick Environmental Testing Apparatus), and PHI (Pneumatic Handling Interface). We will demonstrate that the same BioBrick assembly software can run on multiple plug-and-play LegoRoboBrick instances with different physical dimensions and geometric configurations. The modular design of LegoRoboBricks allows easy extension of new laboratory functionalities in the future. | ||

| + | <h2> Project Goals </h2> | ||

| + | #Low Cost – Robot cost significantly lower than $10,000, the price of a commercial liquid handling robot. (Actual cost of BioBrick-a-Bot prototype: ~$700) | ||

| + | #Hardware Platform that is easily accessible. | ||

| + | #Hardware Design that is easily replicable by other iGEM teams. | ||

| + | #Software Design that is robust, plug and play. Can swap modules from other iGEM teams. | ||

| + | #Design that is easily extensible, to allow future collaboration with other iGEM teams. | ||

| - | + | <h2> The Vision </h2> | |

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | [[Image:LegoRoboBrick.jpg|315px|left]][[Image:LegoRoboBrick2.jpg|315px|left]][[Image:LegoRoboBricks.jpg|313px|right]] | |

| - | + | <h2> Acknowledgements </h2> | |

| - | + | ||

| - | + | Our iGEM project is sponsored by the [http://depts.washington.edu/bioe/ BioEngineering Department] at the [http://www.washington.edu/ University of Washington] | |

| - | + | ||

| - | + | [[Image:bioelogo.jpg]] | |

| - | + | ||

| - | + | [[Image:uw_logo.jpg]] | |

| - | + | ||

| - | + | ||

Latest revision as of 02:25, 22 October 2009

| Home | Team | Project | Modeling | Notebook | Challenges | Miscellaneous |

|---|

Contents |

Abstract

BioBrick-A-Bot: Lego Robot for Automated BioBrick DNA Assembly

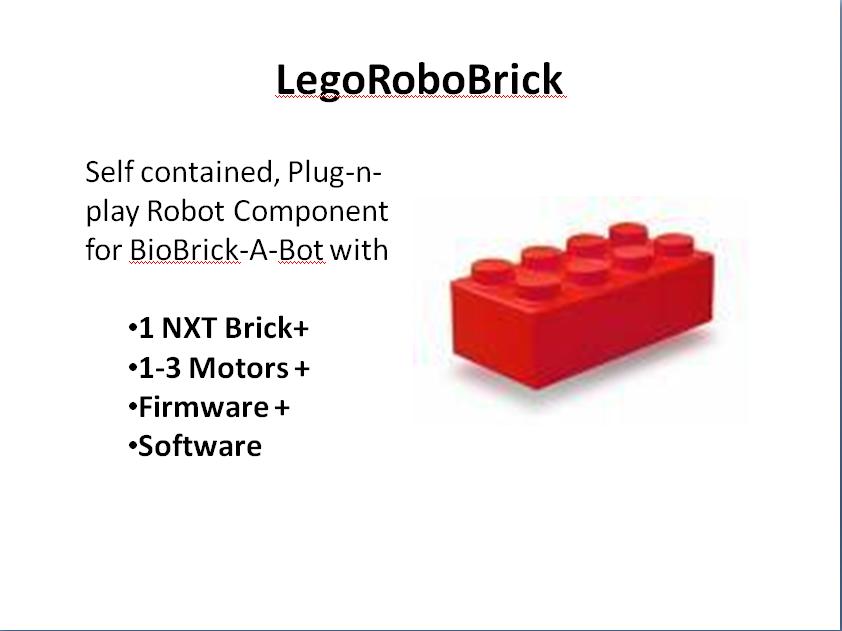

Commercial Liquid Handling Systems are extremely expensive, and are typically beyond the reach of the average molecular biologist interested in performing high throughput methods. To address this problem, we design and implement a liquid handling system built from commonly accessible Legos. Our goal is the automation of BioBrick assembly on a platform that can itself be easily replicated and we demonstrate a proof-of-principle for this system by transferring colored dye solutions on a 96-well plate. We introduce a new concept called LegoRoboBrick. The liquid handling system is build from 3 new LegoRoboBrick modular components: ALPHA (Automated Lego Pipette Head Assembly), BETA (BioBrick Environmental Testing Apparatus), and PHI (Pneumatic Handling Interface). We will demonstrate that the same BioBrick assembly software can run on multiple plug-and-play LegoRoboBrick instances with different physical dimensions and geometric configurations. The modular design of LegoRoboBricks allows easy extension of new laboratory functionalities in the future.

Project Goals

- Low Cost – Robot cost significantly lower than $10,000, the price of a commercial liquid handling robot. (Actual cost of BioBrick-a-Bot prototype: ~$700)

- Hardware Platform that is easily accessible.

- Hardware Design that is easily replicable by other iGEM teams.

- Software Design that is robust, plug and play. Can swap modules from other iGEM teams.

- Design that is easily extensible, to allow future collaboration with other iGEM teams.

The Vision

Acknowledgements

Our iGEM project is sponsored by the [http://depts.washington.edu/bioe/ BioEngineering Department] at the [http://www.washington.edu/ University of Washington]

"

"